Lothmann is the expert IN THE FIELD OF TOOL TECHNOLOGY FOR THE PRODUCTION OF SPECIAL TOOLS

Lothmann Werkzeugtechnik GmbH & Co. KG has been developing and manufacturing exclusively customised special tools since the mid-1980s. In the development of special solutions, the company stands for one hundred percent control and guarantee of the tools.

To date, more than 25,000 special tools have been manufactured in over 10,000 different variants. The company always uses the most modern and reliable machines to manufacture its products.

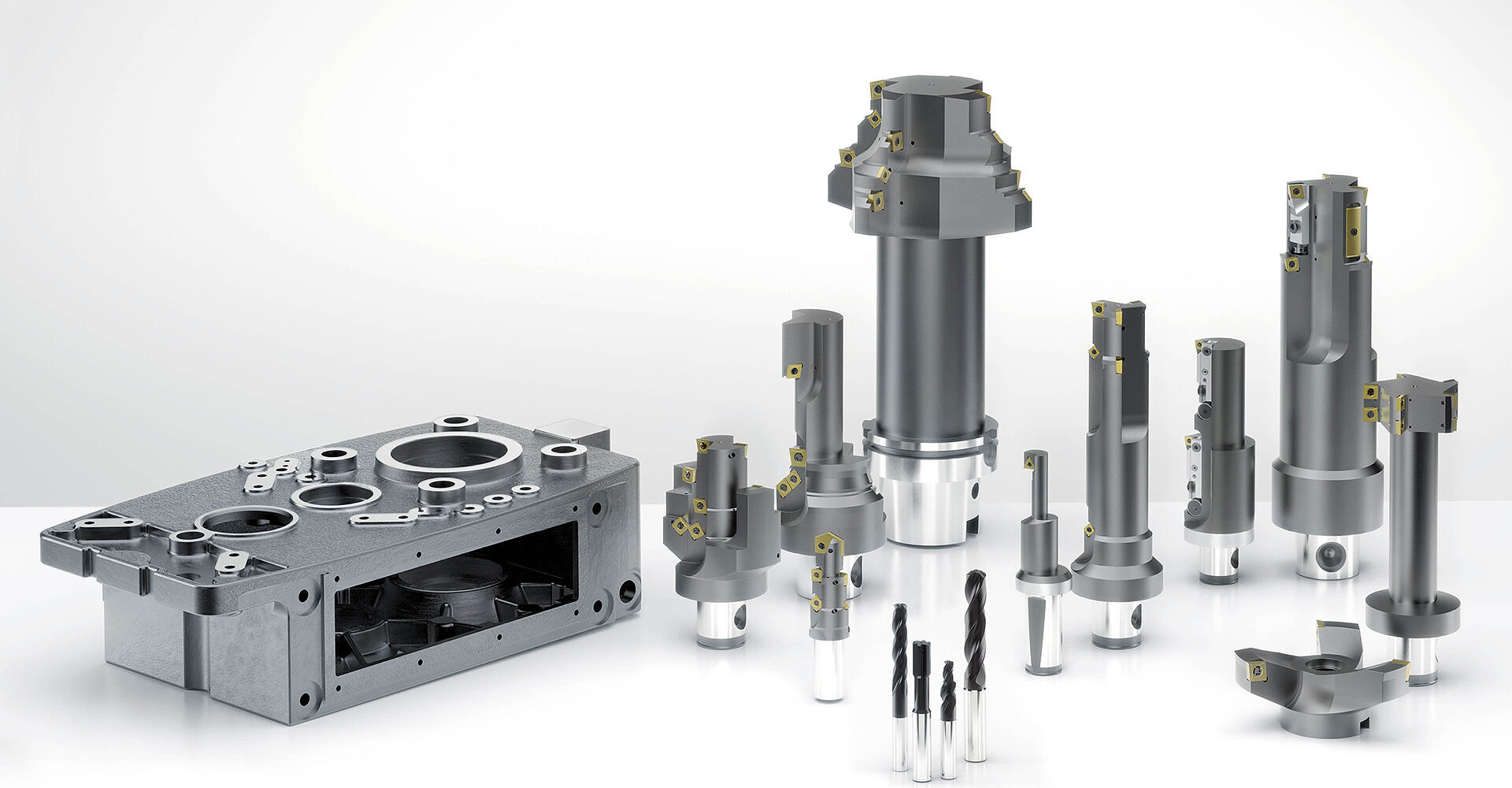

Tool technology products

Lothmann individually develops and manufactures special tools such as countersinking, step drills, solid drills and many more for its customers. These are mainly suitable for drilling work. This includes specific operations such as full drilling, reaming, spindling, chamfering, countersinking, reverse countersinking or overturning as bell tools.

The focus is on performing various operations on a hole with only one tool. Working on CNC machining centres is thus made easier for you and valuable time can be saved.

With your special tool, you can machine a wide variety of materials such as grey cast iron or nodular cast iron as well as steels of all kinds such as low and high-alloy and stainless steel.

Indexable inserts are used for machining various materials. The inserts are purchased from external manufacturers and suppliers. When purchasing, care is always taken to use ISO inserts so that you can easily and inexpensively replace the inserts after wear.

There are different types of inserts that are specially designed for machining different materials. At Lothmann, sintered and coated plates and also plates made of PCD (polycrystalline diamond) as well as CBN (cubic crystalline boron nitride) are used.

Highly modern technology:CAD/CAM PROCESS FROM LOTHMANN

The production of the special tools is carried out with special machines and processes. Lothmann's tool technology is characterised by the specially developed CAD/CAM process. The company does not work on the basis of drawings, but on the basis of a central database with an automatically controlled CAD system. This system stores information on customers and tools and automatically generates quotations and orders. With the recorded data, the special tool can be simulated and tested in 3D CAD. Subsequently, the tools are milled CAM-controlled on the most modern 4-axis machining centres. For the final inspection, all tools are 100% loaded and checked for dimensional accuracy on fully automatic cup and Mapal presetting devices.

Your advantages at a glance

- One hundred percent dimensional control

- Delivery within 3 weeks from receipt of order

- Functional guarantee

- Inexpensive custom-made products

- Enables multiple operations with only one tool

- No regrinding due to the use of ISO inserts

Order your bell tool from Lothmann now