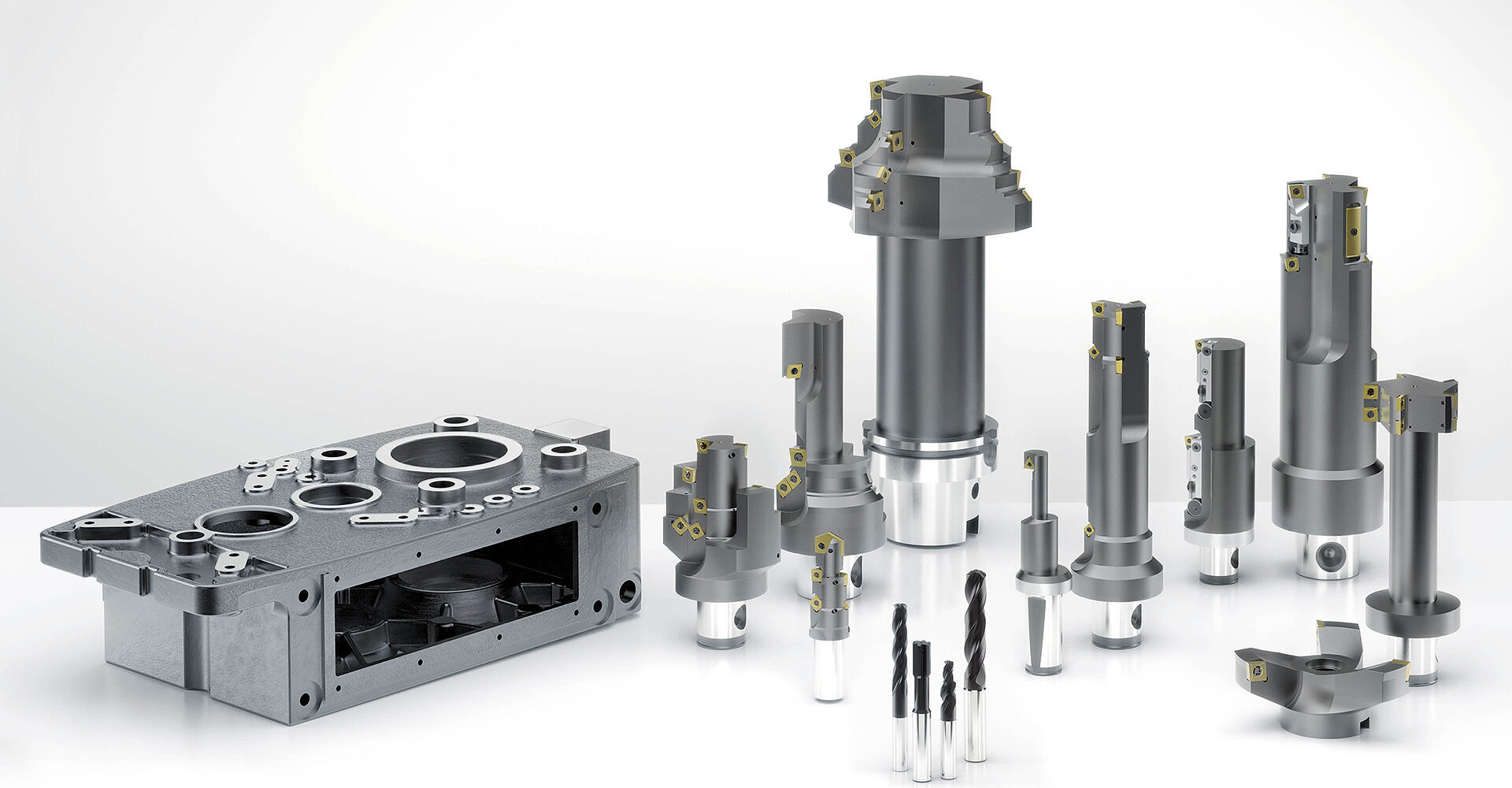

Solid carbide tools

Solid carbide drilling

LOTHMANN offers you an extensive standard range of solid carbide drills for all machining tasks from MAPAL. In addition to two and three-flute tools for solid drilling, the portfolio also includes spot drills, step drills, deep drills and reamers for drilling and reaming in one operation. In addition, solid drills with replaceable head system and indexable inserts are available. Regardless of the material, whether cast materials, non-ferrous metals, steels, modern lightweight materials or materials that are difficult to machine, MAPAL offers the right drill.

Step drilling

Production of core holes and chamfers for metric threads.

- Tritan-Step-Drill - three-fluted step drill with self-centring cross cutting edge for machining threaded core holes without oscillating movement.

- MEGA-Step-Drill - double-edged step drill for the production of threaded core holes

Complex special geometries are easily possible on request.

Please contact us.

Drill reamer

Drilling and reaming in one operation - Tritan-Drill-Reamer:

- Most accurate solution for drill reaming

- Three cutting edges and six guide chamfers

- Self-centring cross cutting edge for improved reaming behaviour

- High positioning accuracy

- Optimum roundness

- With internal cooling

- Tolerance versions ±0.003 mm and H7

Solid carbide milling

LOTHMANN offers you a comprehensive standard programme from MAPAL. This reflects MAPAL's many years of experience, accumulated know-how and high level of process understanding in the field of milling. Process reliability, efficiency and maximum productivity for customers are therefore guaranteed.

After extensive research and development work, designed and simulated with the latest software, produced and tested on the most modern production equipment, our milling cutters reach the customer. In combination with the most efficient cutting materials, we offer you the optimum milling tool for almost all applications and materials.

The high-performance OPTImill end mill programme ensures excellent and reliable results for all machining tasks. Cost-effectiveness and product quality are particularly in focus when meeting customer requirements.

Many special geometries can also be realised. Take a look at the catalogue and contact us.