Back Countersinking from Lothmann SAVE TRANSFORMER OPERATIONS WITH BACK COUNTERSINKING

The backcountersink enables countersinking in hard-to-reach places on the workpiece. Back countersinks are set to a defined position using the spindle orientation and moved eccentrically to plunge position. Then it can be moved into the through-hole and then positioned on the centre of the hole. Now the speed is started and the countersinking operation can be carried out. Analogous to the retraction cycle, the machine is moved out again. The cutting speed for back countersinking should be rather low, the feed rate depends on the material to be machined.

Due to the rigid construction of the tools, a high stability is achieved, which allows a large counterbore diameter. This countersink can be a maximum of twice the diameter of the through hole. In addition, no accessories are required as there are no moving parts.

A great advantage of these tools is the possibility of machining a workpiece on the side facing away from the spindle. Without these tools, workpieces have to be reclamped to allow machining. Back countersinks can also be used in cast workpieces with undercuts. In this way, multi-sided machining can often be realised with significantly reduced reclamping operations.

Details on back countersinksFROM LOTHMANN

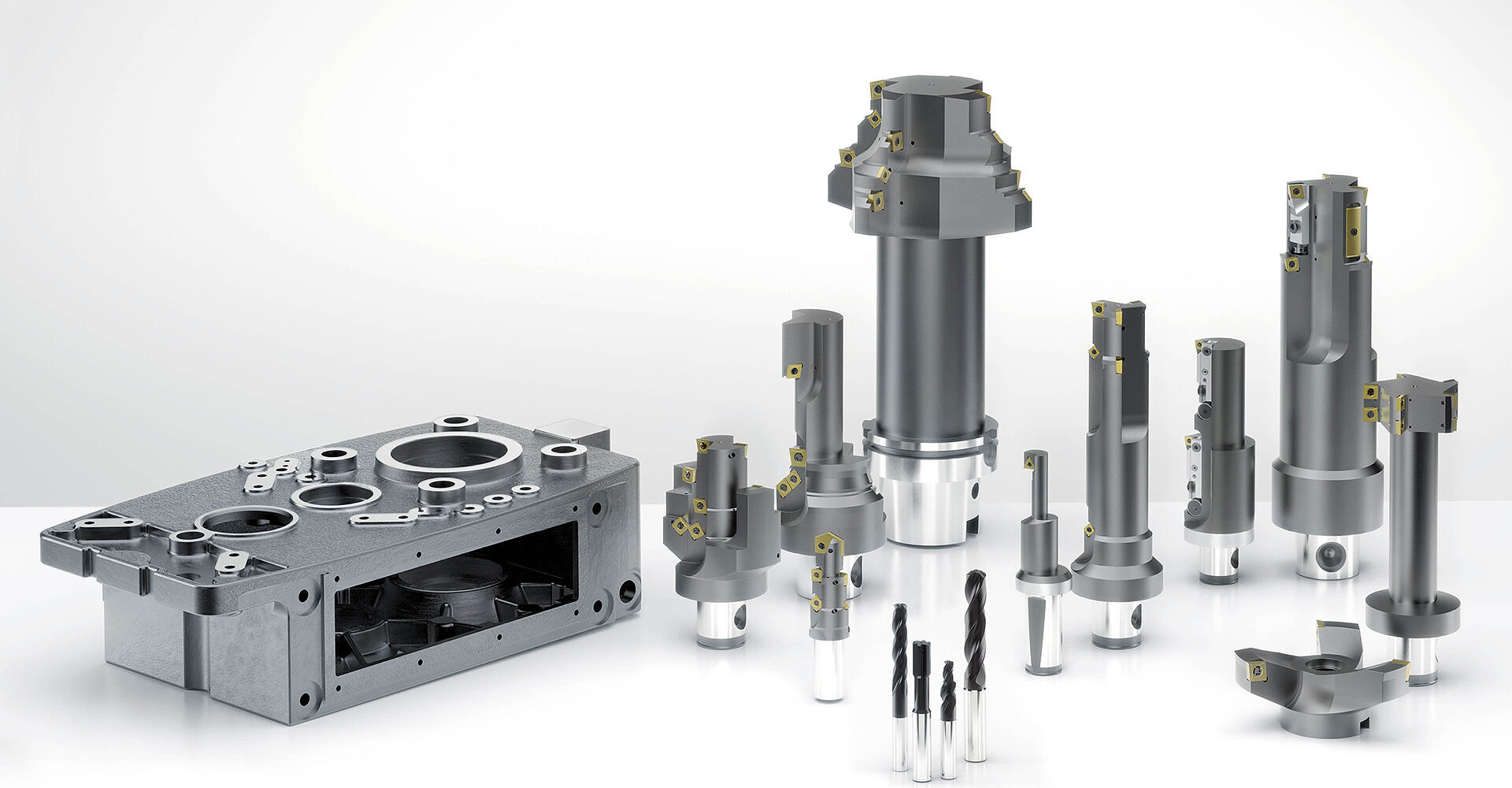

Back countersinks from Lothmann are designed with indexable inserts and can be used for different materials such as steel, aluminium or cast materials by exchanging the insert. Compared to solid carbide or HSS tools, this also eliminates regrinding time. They are usually used on CNC machining centres, from single-part production to large-scale production, and require an existing bore.

Back countersinks are made of heat-treatable steel and are individually adapted to your machining or workpiece. Multiple inserts can also be integrated so that you can produce several concentric contours with just one tool. Fine spindle work with adjustable inserts can be realised as well as simpler roughing work. In addition to the use of ISO inserts, the tool is provided with standardised shanks such as Weldon DIN 1835, Whistle-Notch, straight shank, ABS-compatible, MVS, Varilock or HSK.

Your advantages at a glance:

- Delivery within 3 weeks from receipt of order

- Function guarantee

- Machining possible in hard-to-reach places

- Due to the rigid construction, there are no moving parts such as fold-out cutting edges

- No regrinding due to the use of ISO indexable inserts

Order your back countersinking from Lothmann now