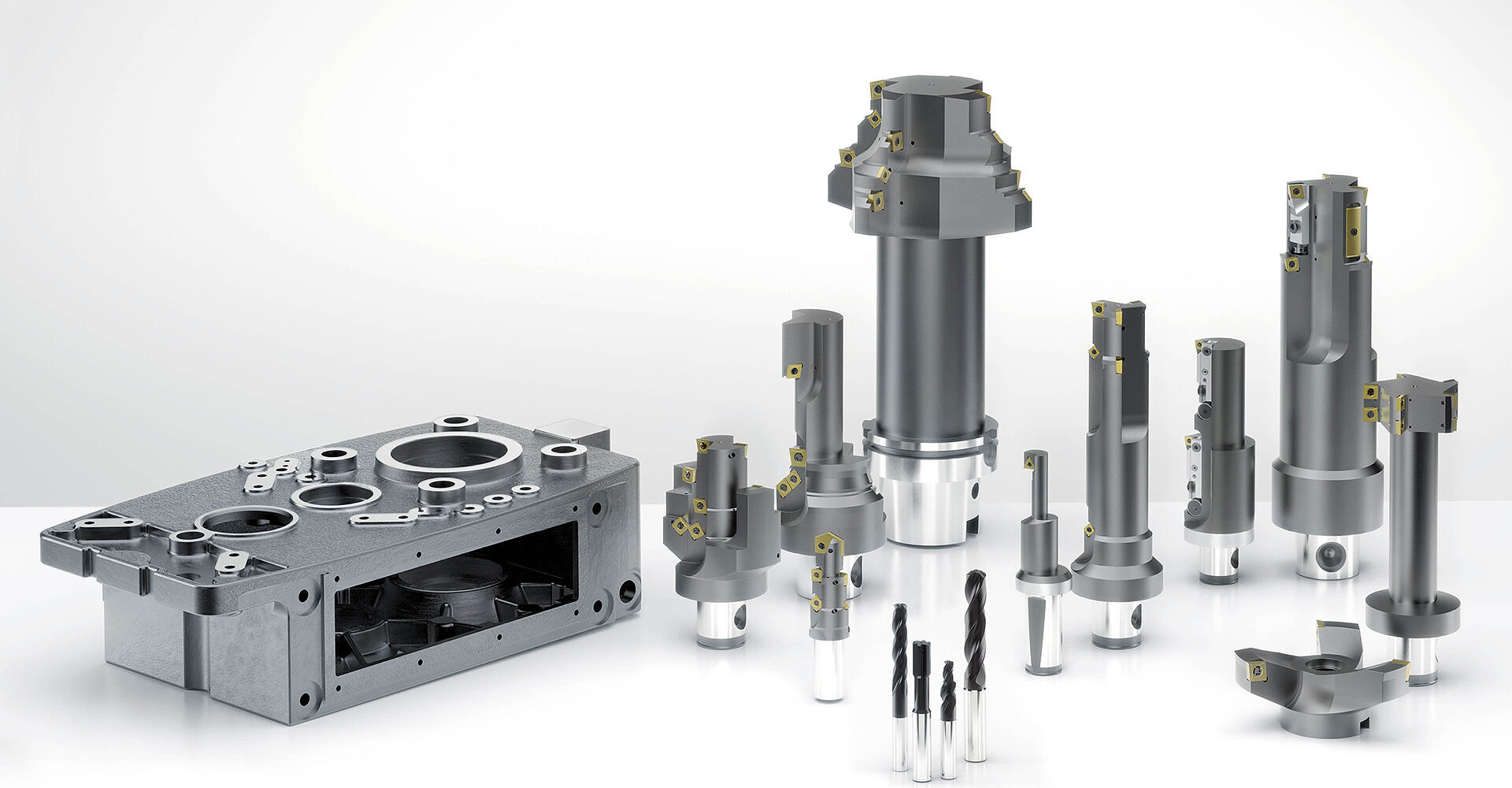

Cutter heads

LOTHMANN is expanding its standard range with the NeoMill range from MAPAL with its face, corner, groove, roll face and high feed milling cutters.

NeoMill stands for maximum productivity and economy, particularly in series production. The basis for the development was the many years of experience with special tools with which the industry very efficiently produces large quantities with constant quality.

Face milling with indexable inserts

Roughing and semi-machining of flat surfaces -> NeoMill-Face: This close pitch shell milling cutter is available with 16 flute radial inserts.

Example: cutter-Ø100mm with number of teeth = 14

Cutting depths of up to 5 mm

MAPAL offers a comprehensive range of indexable inserts for all milling cutters - each in a positive and a negative version. In addition there are inserts with wiper content, which achieve good surface qualities even without adjustment. This effect is particularly noticeable in semi-finish machining.

wear resistance and toughness. The cutting material designation is structured in such a way that toughness increases as the number increases.

PVD-coated cutting materials (HP...) are the first choice for milling K, P and M materials. With them, the longest tool life can be achieved. If high cutting speeds are to be achieved, CVD coated cutting materials (HC...) should be selected.

For non-ferrous materials, uncoated and coated carbide grades (HU.../HP...) are the first choice. From a silicon content of ≥12%, PCD (PU...) is recommended due to the increasing abrasiveness. With PCD, maximum tool life can be achieved, which is why this cutting material is particularly suitable for large series.