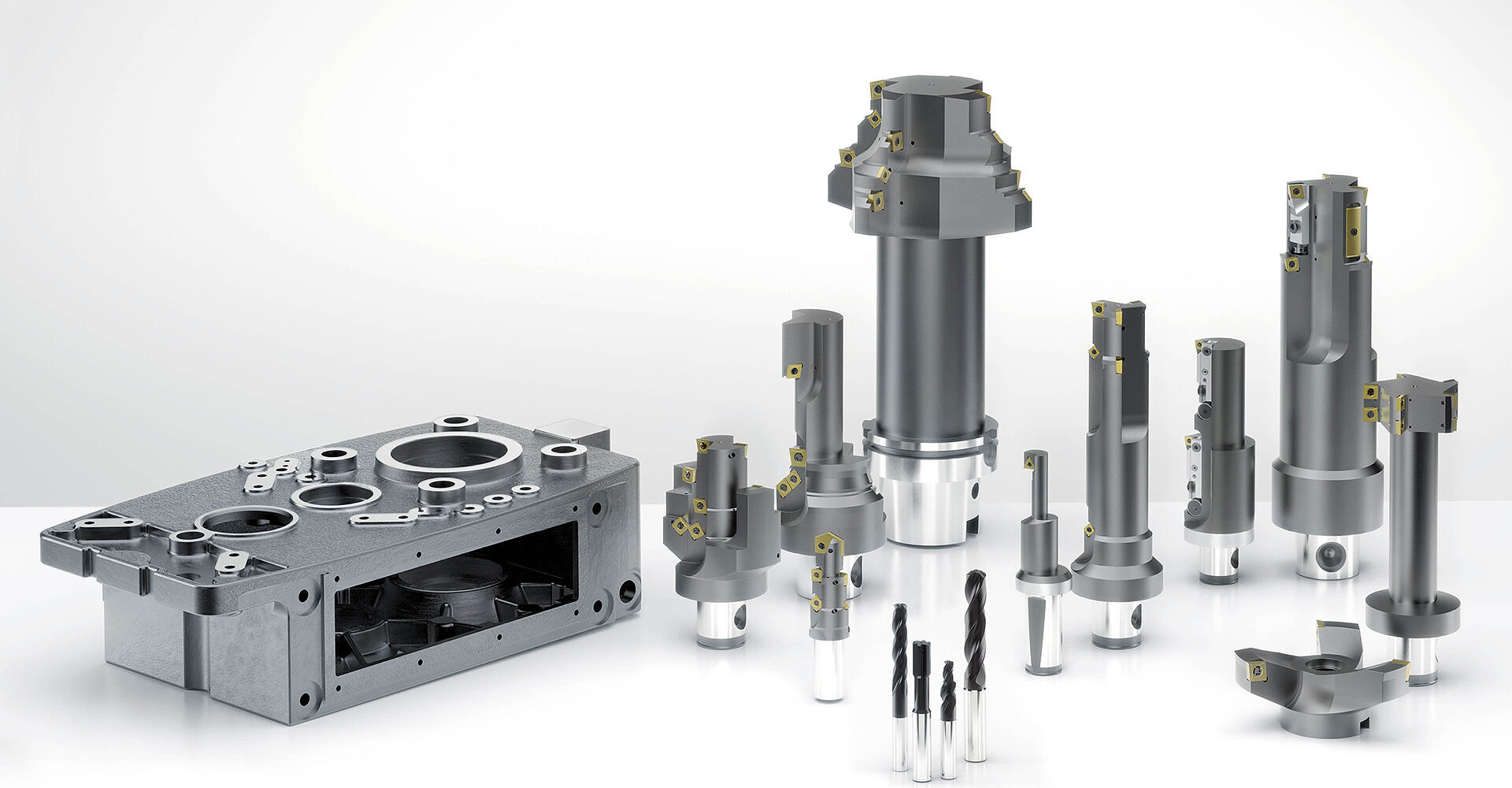

Customized carbide inserts IN SPECIAL CARBIDE DESIGN

Enable the customer to make long-term and efficient use of Lothmann special tools.

Lothmann stands for one hundred percent control and quality. The special tools can be equipped with exchangeable carbide inserts, which very easily contain diameters, deburring or radius transitions.

These cutting edges are individually adapted to the required contour and precision ground.

Due to the high accuracy of the cutting edges, diameter tolerances in a range of ر0.05mm can be achieved without additional adjustment units.

By grinding in different chip grooves, chip control is significantly improved and adapted to the material to be machined.

Properties of inserts in special design

Lothmann prefers to use indexable inserts from MAPAL. In addition to using ISO indexable inserts, Lothmann also manufactures special inserts individually to customer requirements to enable grooving, turning, drilling and milling of complex contours.

This special design means that almost all workpiece geometries can be produced with an exchangeable cutting edge. These special cutting edges can be combined with adjusting elements and can then produce diameter tolerances in a range of ر0.01mm.

The cutting inserts are nowadays very insensitive to cracking. This is mainly made possible by sintering from ultra-fine grain.

The special cutting inserts can all be adapted and optimized to the material with different PVD coatings to achieve a higher performance. The different coatings also protect against rapid wear of the carbide.

Advantages OF THE USED INSERTS IN SPECIAL DESIGN

The use of special inserts significantly reduces the machining time. In addition, tool magazine spaces are saved and optimum concentricity of the bore is achieved. The coated special inserts are suitable for machining steel, cast iron, stainless steels and non-ferrous metals.

The peripherally ground special cutting inserts with a highly positive chip groove are used for machining aluminum and non-ferrous metals.

Blanks made of PCD or CBN can also be inserted into the special cutting edges to enable higher cutting speeds or the machining of hardened steel.