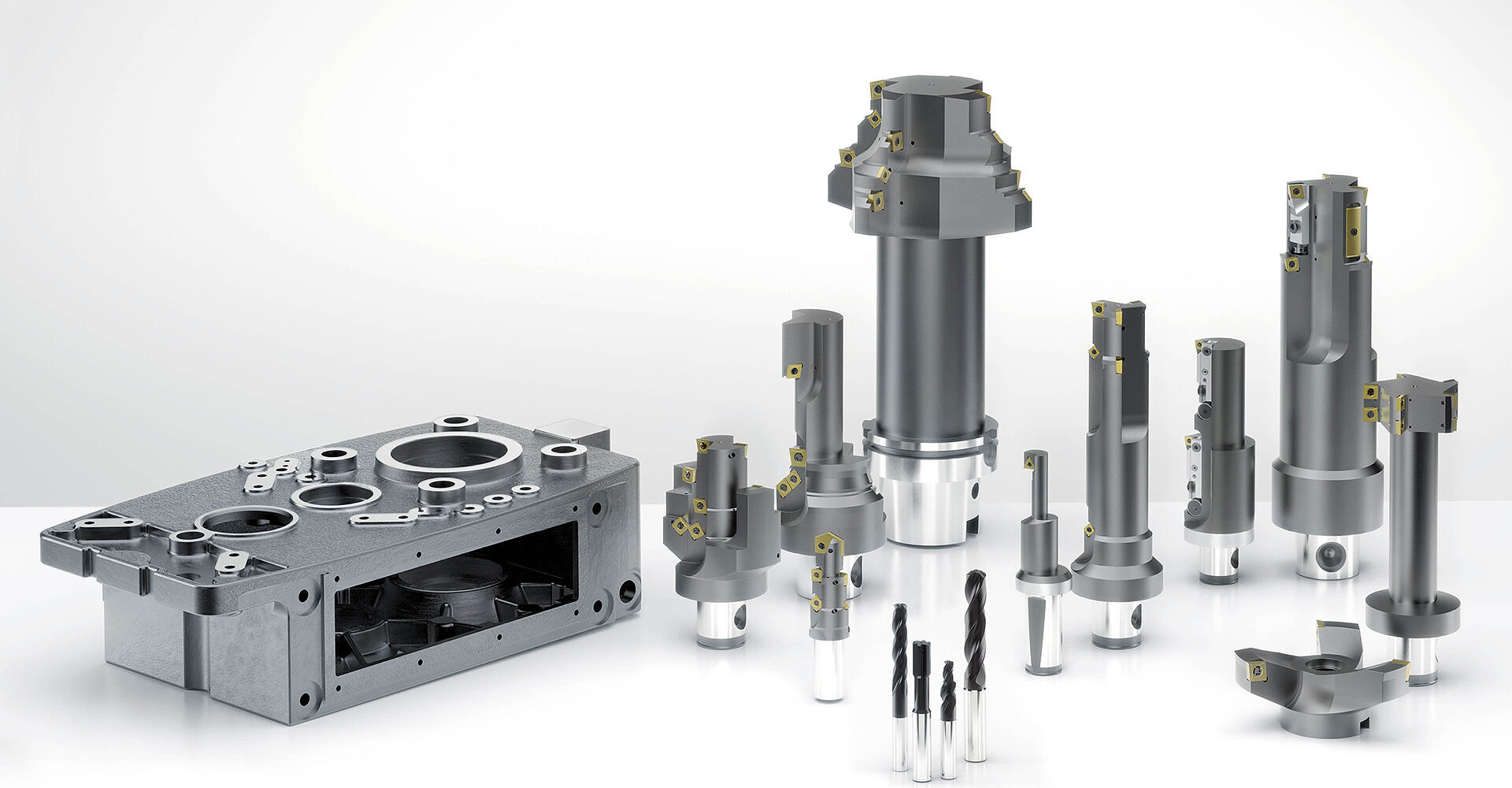

Tool holders

LOTHMANN offers you the newly developed UNIQ hydraulic expansion clamping system from MAPAL. UMIQ enables high machining parameters through excellent stability and accuracy. It minimises self-excited vibrations so that clamped tools are not subjected to micro-vibrations. This in turn leads to a reduced spindle load of up to 5 percent, enables a significantly longer tool life and guarantees optimum surface finishes.

In addition, the brilliant 0surface, which MAPAL produces using a specially developed polishing process, ensures that the chucks are more resistant to dirt and corrosion. Users can clamp the tool reliably in the chuck with little force. This is ensured by "foolproof handling", i.e. simple and self-explanatory handling of the chucks. Especially with the UNIQ Dream Chuck, 4.5° this means a considerable time saving compared to other clamping mechanisms.

Surface chuck MillChuck HB

The MillChuck HB surface chuck convinces with strong clamping, easy handling and high concentricity. The location hole is manufactured much more precisely than usual. This reduces the radial play of the clamped tool and significantly improves concentricity.

The large tolerance on the lateral clamping surface is also compensated. To achieve this, MAPAL uses a spring element in the holder, which enables a defined form fit between the tool and the holder.

Axis-parallel cooling channels in the clamping area also ensure an improved coolant supply.

HighTorque Chuck (HTC)

The HighTorque Chuck (HTC) hydraulic expansion chucks combine the damping properties of hydraulic expansion technology with the high holding forces of shrink technology. Thanks to an innovative manufacturing process, the chucks impress with high torque transmission, ideal damping properties, excellent rigidity of the entire system and a concentricity < 3 μm.

The bending stiffness is 1.4 times that of a conventional shrink fit chuck according to DIN 69882-8. In use, these advantages guarantee a high surface quality on the component, significantly higher machining speeds and thus short machining times.

The properties of the HTC prevent chipping at the tool cutting edge and enable a long service life of the tool used.