Countersinking of the company Lothmann from Ludwigsburg - EFFECTIVELY SAVE TIME IN ALL OPERATIONS

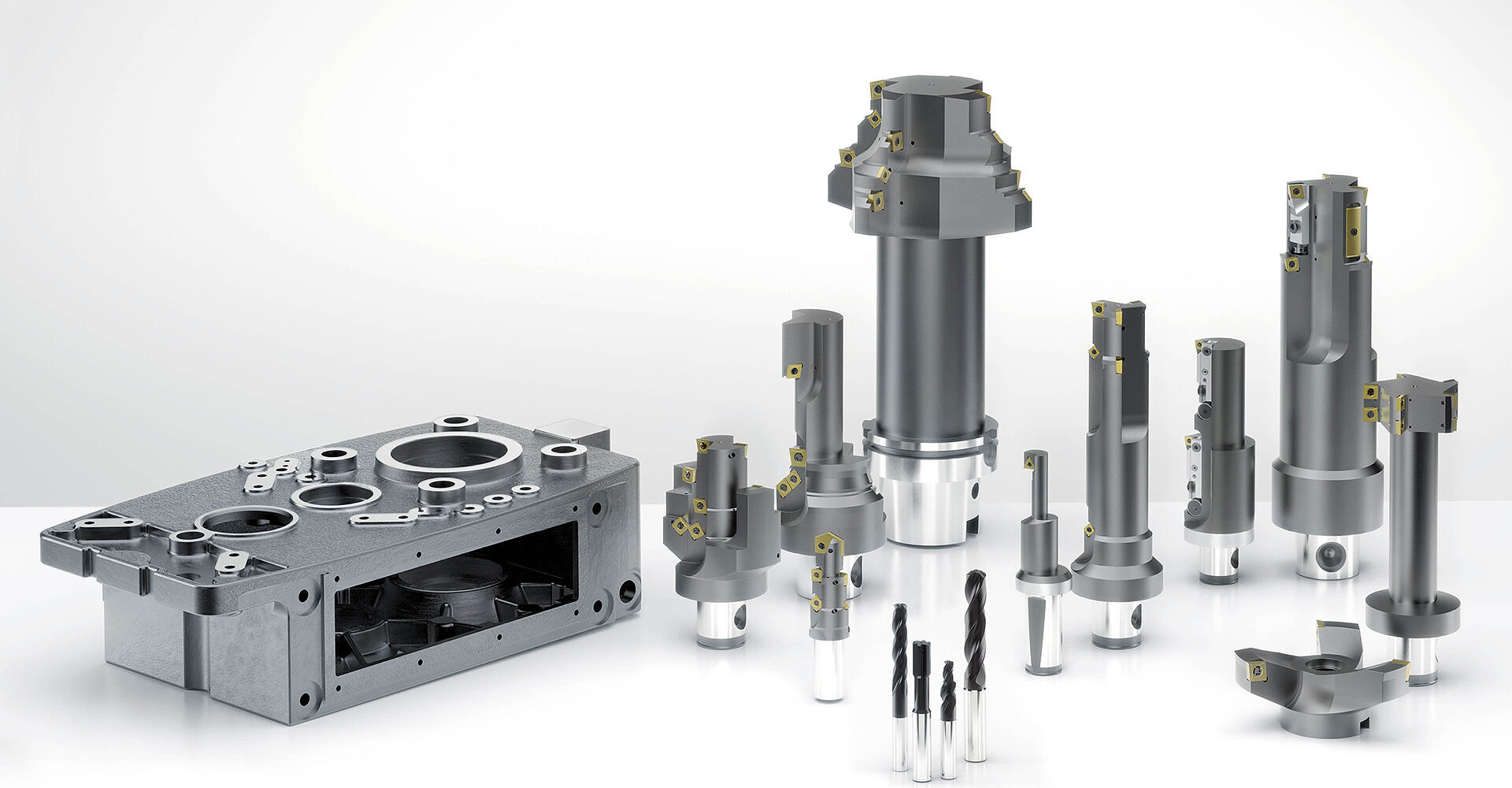

The step countersink from Lothmann, your experienced contact from Ludwigsburg, enables you to simultaneously machine different diameters, chamfers and flat surfaces in a pre-cast or pre-drilled hole on CNC machining centres. It is mainly used in the metalworking industry that works with CNC machining centres. It is mainly used for small and large series production of vehicle parts, hydraulic housings, gearbox housings, general mechanical engineering, commercial vehicles, connecting rods and crankcases. You too can benefit from our step countersink!

Do not hesitate if you are interested in our step countersink? Call us or send us a message - we look forward to receiving your order and will be happy to answer any questions you may have about our products!

Make concentric holes with countersinking

A step countersink can be used to produce various concentric and coaxial contours in a single operation. Countersinking is a machining process with a geometrically determined cutting edge to produce profile or conical surfaces perpendicular to the axis of rotation. An existing pre-drilled, pre-cast or pre-punched hole is required, which can be extended by the countersinking process to include further contour elements such as chamfers, fits, thread core diameters and co. A distinction is made between the following types:

- Face countersinking (for producing a protruding, flat surface)

- Face countersinking (for producing recessed, flat surfaces, for example for countersinking a cylinder head screw for production)

- Profile countersinking (for producing a tapered or profiled countersink)

- Deburring

- Fine spindles

All step countersinks are custom-designed for the corresponding application area and are equipped with modern ISO indexable inserts made of solid carbide, PCD or CBN. The machining of different materials such as steel, aluminium, cast materials or copper alloys can be realised by simply exchanging the cutting insert.

In contrast to ground form countersinks made of HSS or solid carbide, a step countersink with indexable inserts can be used without long downtimes, as time-consuming regrinding is not necessary. Special forms are taper countersinks or flat countersinks, which can also be offered with indexable inserts.

The main areas of application are in control block production (hydraulics), housing machining (pumps, compressors, drives, motors) and many other areas.

Convince yourself of the advantages of our countersinking tools

Due to the specific design of the step countersink, the shank, the machining strategy and the preferred insert manufacturer (such as Sandvik, Walter, Kennametal, Komet, Seco, Mitsubishi, ...) can be determined together with the customer. They are usually used on CNC machining centres and CNC lathes from medium to large-scale production.

Already during the production process, the step countersinks are measured several times so that a continuous dimensional accuracy is guaranteed. The measurements are carried out on high-precision optical measuring devices. Before delivery, our quality assurance department carries out a 100% check and the results are recorded and archived.

We have convinced you? Here you will find all the advantages of our step countersinks at a glance:

- One hundred percent dimensional control

- Delivery within 3 weeks from receipt of order

- Functional guarantee

- Cost-effective special production for complex workpiece geometries

- No regrinding due to the use of ISO inserts

Produce concentric bores with countersinking tools

With a countersinking tool, various concentric and coaxial contours can be produced in one operation. Countersinking is a machining process with a geometrically defined cutting edge to produce profile or conical surfaces perpendicular to the axis of rotation. An existing e.g. pre-drilled, pre-cast or pre-punched hole is required, which can be extended by the countersinking process to include further contour elements such as chamfers, fits, thread core diameters, etc.

A distinction is made between the following types:

- Face countersinking for the production of a protruding, flat surface

- Countersinking to produce recessed, flat surfaces, for example for countersinking a cylinder head screw to produce recessed, flat surfaces, for example for countersinking a cylinder head screw

- Profile countersinking for producing a tapered or profiled countersink

All Lothmann tools are custom designed for the corresponding application area and are equipped with modern ISO indexable inserts made of solid carbide, PCD or CBN. The machining of different materials such as steel, aluminium, cast materials or copper alloys can be realised by simply exchanging the cutting insert.

In contrast to ground form countersinks made of HSS or solid carbide, a countersinking tool with indexable inserts can be used without long downtimes, as time-consuming regrinding is not necessary. Special forms of profile countersinks are taper countersinks or flat countersinks, which can also be offered with indexable inserts.

Due to the specific design of the tools, the shank, the machining strategy and the preferred insert manufacturer (e.g. Sandvik, Walter, Kennametal, Komet, Seco, Mitsubishi, ...) can be determined together with the customer.

Countersinking tools from Lothmann can be used for the machining processes profile countersinking, face countersinking, face countersinking, deburring or fine spindling. They are usually used on CNC machining centres and CNC lathes from medium to large-scale production.

Measuring the countersinking tools

Countersinks are measured several times during the production process to ensure continuous dimensional accuracy. The measurements are carried out on high-precision optical measuring devices.

Before the tools are delivered, a 100% check is carried out by our quality assurance department and the results are recorded and archived. The main areas of application for the tools are in control block production (hydraulics), housing machining (pumps, compressors, drives, motors) and much more. In combination with adjustable ISO indexable inserts, high-precision fits can also be produced.

- One hundred percent dimensional control

- Delivery within 3 weeks from receipt of order

- Functional guarantee

- Cost-effective special production for complex workpiece geometries

- No regrinding due to the use of ISO inserts

- No regrinding due to the use of ISO inserts

Order your countersinking tool from Lothmann now