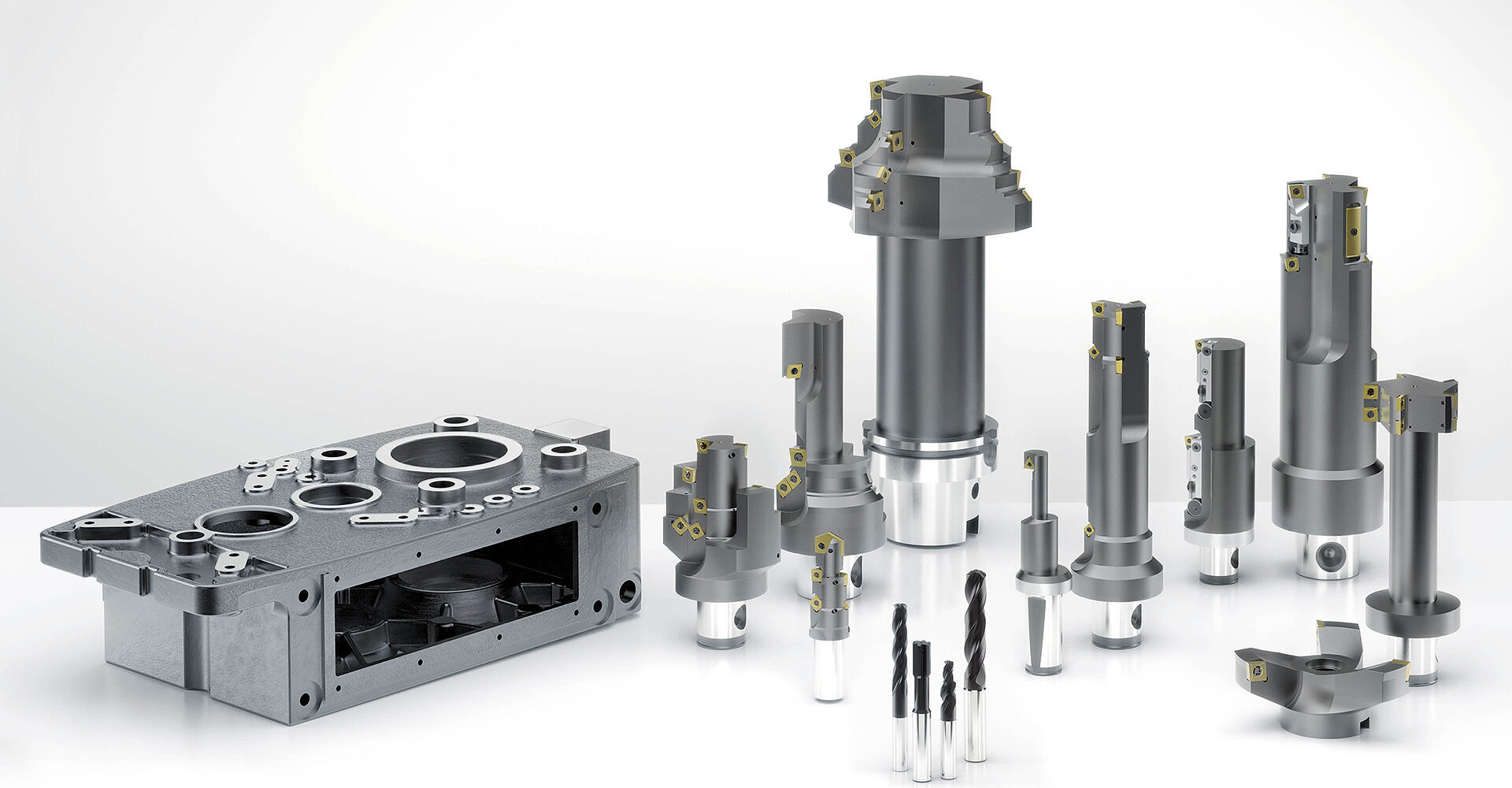

Polygonal shank taper from Lothmann in Ludwigsburg - The innovative interface designed for cutting tools

The polygonal shank taper (PSK) is an innovative interface designed for cutting tools, distinguished by its exceptional precision and stability. The key advantages of the PSK include:

- High Repeatability:

The PSK provides outstanding repeatability, which ensures that tools can be accurately fixed in the same position after each change. This feature is crucial for maintaining consistent machining quality and reducing the risk of errors. - Short Changeover Times:

With its quick-change functionality, the PSK allows for rapid and straightforward tool exchanges. This capability significantly minimizes machine downtime, enhancing overall productivity in manufacturing processes. - High Torque Transmission:

The PSK is engineered to handle high torque levels, making it particularly beneficial for demanding machining tasks that require substantial force. This feature ensures that the tools can perform effectively even under heavy loads. - High Bending Stiffness:

The design of the PSK incorporates high bending stiffness, which contributes to increased stability and precision during the machining process. This characteristic helps to maintain tool integrity and performance, even in challenging operational conditions. - Self-Centering:

The PSK features a self-centering mechanism, which further enhances accuracy and efficiency. This automatic alignment reduces setup time and ensures that tools are positioned correctly for optimal performance.

The polygonal shank taper is available for our tools in the following sizes:

PSK 32, PSK 40, PSK 50, PSK 63, and PSK 80.

Standards and Norms

The PSK adheres to the ISO 26623-1 standard, which outlines the requirements for the interface. This compliance guarantees that the tools are compatible and interchangeable on a global scale, facilitating seamless integration into various manufacturing environments.

In summary, the polygonal shank taper represents a cutting-edge technology that significantly enhances efficiency and precision in machining operations. Its high repeatability, short changeover times, and capability to transmit high torques make the PSK an invaluable asset for any modern manufacturing setting, driving productivity and ensuring high-quality results.